What precautions should be taken in wire harness processing

Nowadays, wire harness processing has also become a very common process, especially in the electronics industry, where the existence of these processes can also be seen. In order to ensure the quality of the process and ensure the smooth completion of the entire machining, it is still necessary to pay attention to multiple aspects during the machining process in order to ensure the smooth completion of the machining process.

Firstly, carry out corresponding inspections

Before processing the wiring harness, it is important to conduct corresponding inspections first. Many companies fail to conduct appropriate inspections before processing, resulting in problems during subsequent processing. Therefore, it is necessary to conduct a thorough inspection first, checking the size of the wires to see if they meet the corresponding requirements, as well as whether the model is correct, including ensuring that the cut is flat, without scratching the wires, and without any dirt.

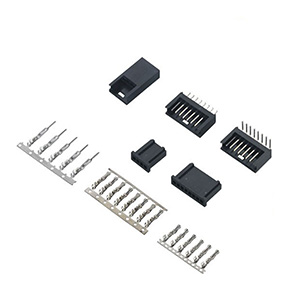

Wiring harness processing

Secondly, peeling off the inner and outer skin

It's not just about checking the wires properly, but also paying attention to peeling the inner or outer layer, checking whether the peeling mouth is neat and the size is correct. And whether there is any damage to the internal core wire, whether there is any short falling, and also when performing half stripping, it is important to pay attention to the insulation not falling off, which is also very important.

Thirdly, understand the processing technology

In addition to checking the wiring harness during processing, it is also important to have a good understanding of the entire processing technology. It is necessary to first understand the process specifications and requirements of the entire wiring harness during processing, and then complete the specific processing according to the correct requirements. If enterprise users do not know how to process, they can choose to use professional personnel from the manufacturer to complete the specific production and processing.

Fourth, make preparations before processing

Many enterprises encounter some problems during the processing mainly because they have not done corresponding preparatory work. Before processing the wire harness, it is necessary to make corresponding preparations and check whether the temperature of the soldering furnace is correct. Before conducting preliminary soldering, it is also important to tidy up the copper wire and core wire, check for any bending or branching, and only after making the necessary preparations can the processing be carried out better.

Wire harness processing has indeed become a common process in various industries. If you want to do a good job in processing work and ensure the final processing quality, you need to pay more attention to these aspects, especially conducting corresponding inspections and preparations, which are crucial to successfully complete the processing work.

Firstly, carry out corresponding inspections

Before processing the wiring harness, it is important to conduct corresponding inspections first. Many companies fail to conduct appropriate inspections before processing, resulting in problems during subsequent processing. Therefore, it is necessary to conduct a thorough inspection first, checking the size of the wires to see if they meet the corresponding requirements, as well as whether the model is correct, including ensuring that the cut is flat, without scratching the wires, and without any dirt.

Wiring harness processing

Secondly, peeling off the inner and outer skin

It's not just about checking the wires properly, but also paying attention to peeling the inner or outer layer, checking whether the peeling mouth is neat and the size is correct. And whether there is any damage to the internal core wire, whether there is any short falling, and also when performing half stripping, it is important to pay attention to the insulation not falling off, which is also very important.

Thirdly, understand the processing technology

In addition to checking the wiring harness during processing, it is also important to have a good understanding of the entire processing technology. It is necessary to first understand the process specifications and requirements of the entire wiring harness during processing, and then complete the specific processing according to the correct requirements. If enterprise users do not know how to process, they can choose to use professional personnel from the manufacturer to complete the specific production and processing.

Fourth, make preparations before processing

Many enterprises encounter some problems during the processing mainly because they have not done corresponding preparatory work. Before processing the wire harness, it is necessary to make corresponding preparations and check whether the temperature of the soldering furnace is correct. Before conducting preliminary soldering, it is also important to tidy up the copper wire and core wire, check for any bending or branching, and only after making the necessary preparations can the processing be carried out better.

Wire harness processing has indeed become a common process in various industries. If you want to do a good job in processing work and ensure the final processing quality, you need to pay more attention to these aspects, especially conducting corresponding inspections and preparations, which are crucial to successfully complete the processing work.

Related Articles and Blogs

1

What are the performance characteristics of connectors

What are the connection selection methods for terminal blocks

What are the connection selection methods for terminal blocks

What precautions should be taken in wire harness processing

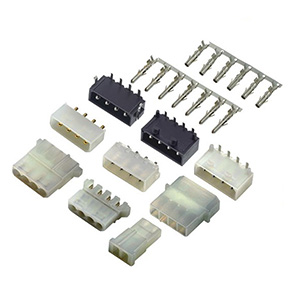

Wiring harness processing

Selection of connectors

- Telephone:

- 086-021-52707396

- Sales Manager:

- Manager Duan 086-13816630069

- Email:

- dxj@gaolin-china.com